EAM Software: What Is It & Why Does It Matter?

EAM Software

When you run a large facility, think manufacturing plant, hospital campus, or fleet operation, you have a mountain of assets. Machines, vehicles, buildings, tools… each part needs care. Luckily, the use of Enterprise Asset Management Software helps track physical assets. Anything that needs maintenance or tracking goes into the system. EAM software stores key info like asset location, usage, repair history, and value.

This isn’t just a fancy spreadsheet. A good EAM system can handle everything from inspections to work orders. With EAM software in place, you click into a dashboard, spot assets nearing worn-out status, and assign maintenance before failure. You’re managing with foresight, not after the crash.

Maintenance Always Matters

Machines break. That’s business. But if your team is always fixing problems as they pop up, you’re wasting time and money. Preventive maintenance is the smarter move.

EAM software helps you plan ahead. You can set schedules, track usage, and know when it’s time for repairs before things fall apart. This leads to better safety, lower costs, and happier workers because no one likes surprises in the form of broken gear.

Real-Time Tracking Changes Everything

Let’s say you run a factory. You’ve got 30 machines, and two of them keep shutting down. With EAM software, you can track when, why, and how often it happens. You can even see if it’s the same technician doing the fix each time.

That kind of detail makes it easier to find patterns and fix root problems. Over time, it saves money. It also helps with compliance. You’ll have records ready if someone ever asks, “When was this last serviced?”

The Difference Between EAM and CMMS

CMMS stands for Computerized Maintenance Management System. It’s good for basic repair tracking. But EAM goes bigger.

EAM includes the full asset life cycle. From purchase to retirement. From daily use to annual inspections. If CMMS is a maintenance logbook, EAM is the full operations guide.

Here’s how they differ:

- CMMS: Tracks work orders, basic maintenance, and service history

- EAM: Adds budgeting, forecasting, asset lifecycle management, and long-term planning

If you’re running a large company or managing assets in multiple locations, EAM software is usually the better choice.

Where EAM Software Works Best

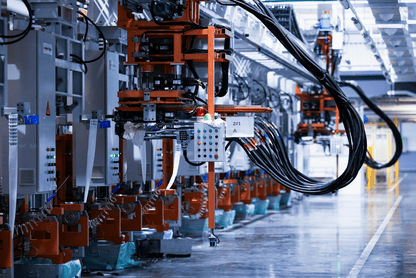

EAM systems shine in industries where assets play a big role. Think utilities, transportation, manufacturing, healthcare, and even government buildings.

Why? Because those businesses run on expensive equipment and strict maintenance rules. They can’t afford downtime. EAM gives them a way to stay ahead, keep costs predictable, and reduce risk.

Let’s break it down further:

- Manufacturing: Keep machines running

- Healthcare: Track and service critical medical tools

- Utilities: Manage inspections for power lines, transformers, and pipes

The more complex the environment, the more useful EAM becomes.

Features That Actually Make a Difference

Some EAMs are bloated with features you won’t use. So we suggest you to focus on what adds real value:

- Asset tracking: Know where things are and their condition

- Preventive maintenance: Schedule it before stuff breaks

- Work order management: Assign tasks, track completion, and collect notes

- Inventory control: Stop over-ordering parts

Simple features like mobile access matter too. Field techs should scan assets with tablets, update status on the go, and sync when they return. That level of ease boosts adoption, and software only helps if people use it. The best systems are easy to use and save your team time every day.

Picking the Right Software for Your Business

Buying EAM software isn’t like grabbing an app off the shelf. You need to think about your current process. What’s missing? What slows your team down?

Start with these questions:

- Do we track asset maintenance at all?

- How much downtime do we experience?

- Are work orders getting lost or delayed?

- Do our technicians have the tools they need to do their job faster?

A good EAM system should fit your needs today and grow with you over time.

Costs, Returns, and Long-Term Payoff

EAM software is an investment. It can feel expensive upfront, especially for small to midsize businesses. But skipping it often means higher costs later.

Think about what downtime costs you per hour. Now multiply that by a few unexpected breakdowns. Or missed inspections that lead to penalties. Or duplicated efforts because records are all over the place.

With EAM, you gain control. You spend smarter. And you create systems that help the team do more with less. That’s the real return.

Final Thoughts: Make Maintenance a Strategy

EAM software brings structure to asset management. It turns guesswork into planning. It brings teams out of reaction mode and into preparation mode.

If you’re tired of last-minute repairs, rising maintenance costs, or missing information, this is the tool to explore. Even small steps toward better tracking can lead to big improvements.

So whether you’re running a warehouse, a hospital, or a power plant, start thinking about your equipment as more than just tools. They’re long-term investments. And like any investment, they need smart management.